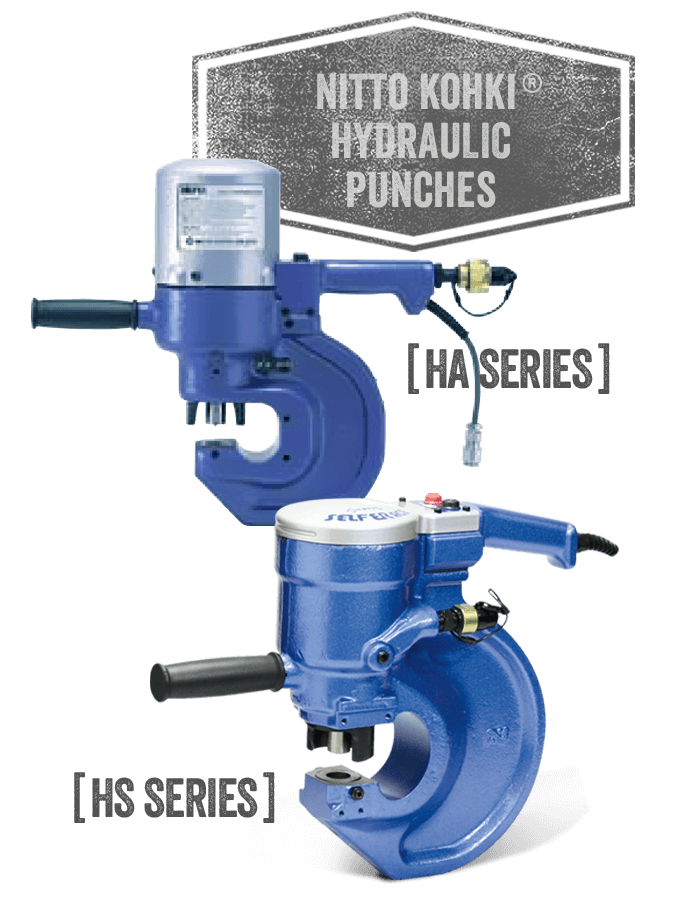

Hydraulic Bench Punch

Our machine range is capable of quickly punching various special-shaped holes such as oval and round. It also includes a backup button that allows you to stop the punch instantly at any time. This single-acting hydraulic comes in a compact design, powered by a hydraulic engine. There are also manual and electronic hydraulic pump options.

Equivalently, the powerful motor of this machine produces an output force for a hole that reaches 31T. Its outer surfaces are painted to protect against rust, provide strength and durability. The hydraulic pump can punch holes quickly.